Prototypes: Exploring the Best Options for Plastic Part Testing

Prototype Plastic Parts

Creating a new plastic part with significant tooling costs requires careful consideration and testing before committing to full-scale production. Prototyping plastic parts is an important phase that allows us to evaluate the part’s functionality quickly, avoiding costly tool adjustments and assuring optimal performance and lifetime. SPI Group provides a variety of prototyping solutions, including modeling, fast prototyping, and pull-ahead cavities, by leveraging advanced CAD tools such as Solid Works.

Modeling: Traditional Prototype Approach

Professionally produced models composed of wood, plastic, or metal were traditionally used for performance testing. While computer-aided solid modeling has reduced the requirement for physical prototypes, fully functional prototype models are still useful, particularly for intricate sections. Building accurate models helps gather essential data, minimize design iterations, and save time and money during development.

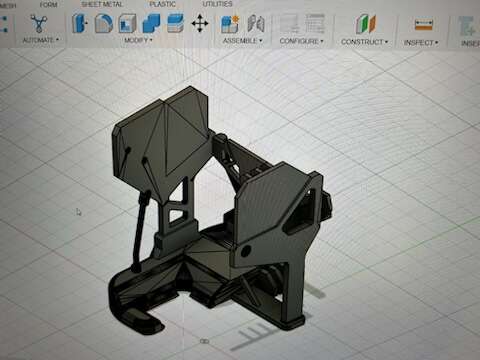

Rapid Prototyping / Plastic Part Printing: Modern Efficiency

Rapid prototyping, also known as 3D printing or additive manufacturing, transforms the prototyping process by saving time and money. This method is excellent for determining size and fit, but it may not correctly represent strength and toughness due to differences in material properties. SPI Group uses this technique for both injection molding and blow molding projects, saving our customers time and money.

Pull Ahead Cavities: A Strategic Solution

For medium to small plastic parts produced using multiple cavity tools, the pull-ahead cavity approach is often advantageous. Instead of building all cavities at once, a single cavity is constructed and used to make prototype pieces. Testing on this “pull-ahead” cavity enables necessary modifications to be made before constructing future cavities. This method is especially useful when multiple pieces are required for testing, putting the strength and toughness properties to the test.

Partner with SPI Group for Optimal Prototyping

When considering prototype plastic parts, SPI Group stands ready to provide the best prototyping solutions tailored to your unique needs. Whether through traditional modeling, rapid prototyping, or pull-ahead cavities, SPI’s expertise and advanced technologies ensure efficient product development and accurate validation before moving to full-scale production. Please contact us if you are planning your next prototype project; we will explore the best solutions and materials to achieve a successful initial stage before progressing into production. We are waiting to partner with you!