When you’re looking to design a plastic part or entire plastic product, the process generally follows a simple series of steps. However, the method of production you end up using may be any one of several which is determined by the geometry of the part and the functional requirements placed upon it. It’s important to understand molded plastic parts manufacturing.

When you’re looking to design a plastic part or entire plastic product, the process generally follows a simple series of steps. However, the method of production you end up using may be any one of several which is determined by the geometry of the part and the functional requirements placed upon it. It’s important to understand molded plastic parts manufacturing.

Fortunately, the steps are pretty straightforward once you understand the sequence of events needed to take a project from an initial idea to a final part design and manufacturing process. Below is a simple road map to consider and some examples of a couple of the most common molded plastic parts manufacturing methods. Go from initial design to a completed product.

1. Coming Up With A Design

The first step is coming up with a design for your plastic molded part. This can begin with something as simple as a sketch on the back of a napkin. Your initial design should ultimately incorporate enough detail to have an engineer draw up a 3D Model of your proposed plastic part. This is the beginning point from which you will make all the changes and refine the initial ideas into a working representation of your parts. Also from this drawing you may want to get an actual prototype built.

During this phase it is very helpful to work with a design team, which generally includes engineering, sales and manufacturing technical expertise, to assist with finalizing your design and preparing it for the next phase of the process. It’s important to define what type of testing needs to be done to prove out the feasibility of your part design and functionality.

2. Determine the molding process to be used.

During this phase you’ll need to decide which type of molding method will be best for your product. The type of plastic molding process selected will depend upon your initial design, quantities needed and overall functionality of the part. There are several plastic molding processes available. Five of the more common general broad categories are Injection Molding, Blow Molding, Rotational Molding, Extrusion Molding and Thermoset Molding. Each of these processes have more specific sub groups of processes within them. The general category is all you will need at the beginning of your project. From these categories you will quickly narrow to the primary molding process most appropriate to your part.

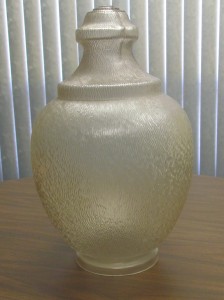

Two of the most common forms of molding plastic include blow molding and injection molding. Injection molding is used to produce parts made with a simple open and close function of the mold. Wall thickness and close tolerances can generally be held more consistent with injection molding than blow molding. Blow molding is used to produce hollow plastic parts and can accommodate unusual shapes. Both injection molding and blow molding can use a very wide range of resin materials that exhibit a similar wide range of physical properties, both visually and to the touch. Impact strength, flexible toughness, pliability, and many other characteristics can be achieved by both injection and blow molding.

3. Prototype Your Design

During the prototyping phase, if your budget allows, you’ll develop a plastic prototype that will resemble the final molded plastic part. The plastic prototype may be created using rapid prototype resin printing, soft tooling, or use single cavity pull-ahead tooling. There are many prototype processes available today. The design team will determine the best fit for your project.

The budget for your project will also influence the number of times you can afford to go back and forth between your mock-up design and initial prototype. You want to keep the number of iterations to a minimum. You will be working closely with the designers and product engineers at this stage. The manufacturing team will play a large role in guiding what can and cannot be molded using the various plastic molding technologies.

Once you’ve finalized your prototype you’ll move forward to getting the final mold designed for your plastic part or product. You will now be working with tool design engineers to determine the most appropriate way for your part to be arranged in the actual tool, also referred to as the mold. This process should, if at all possible, include the manufacturing technical team to determine how a tool, or mold, should be designed to run properly in the molding equipment from which the part will ultimately be produced.

4. Manufacture Your Item

The plastic manufacturing company you use to produce your final plastic part will depend upon many factors. The type of molding you’re going to use for your final product, such as size of part and annual projected quantities will lead you to the group of processors for consideration. Most manufacturing facilities have specific specialties at which they excel. Some plastic molding companies do just the part manufacturing. Others do secondary assembly. Some manufacturing companies take the process all the way to finished goods. Fulfillment including packaging and shipping is not available from all molded plastic part manufacturers. You will also want to discuss the volume of parts each plastic manufacturer can handle. Small plastic manufacturing plants may not be suited well for large volumes. Others specialize in short run, highly technical molding. SPI Blow Molding is one of the Custom Industrial Molders capable of very difficult challenges. We range from high volume parts for the agricultural industry to low volume parts for the Medical Industry. Large tanks for the recreational vehicle industry to small injection molded parts for the electronics industry. SPI Industries’ injection molding resume covers a very diverse range of products from plumbing fixtures to freight securement systems.

Early discussions with potential manufacturers about volume, turn around, types of plastic resins available and fulfillment is highly recommended. It’s important to work with a plastics manufacturing facility that has experience producing similar style plastic parts, or is proficient in the style of plastic molding your product requires. You will also want to consider if you simply need parts or if you need the project handled from concept to completion. You may consider location of a plastic molding facility. SPI Industries and SPI blow molding are located in the South West Region of Lower Michigan and North West Region of Indiana. SPI Plants produce plastic molded parts for companies located in more than simply the Great Lakes Region. Our customers are located throughout the country. Depending on the needs of the customer, location is not always the most important criteria.

5. Package The Goods

Once your molded plastic parts ha ve been produced they may then be packaged and delivered to your facility for assembly and further distribution, or could be delivered directly to your customers. Discuss in detail your overall need for assistance with any and all steps in the manufacturing process.

ve been produced they may then be packaged and delivered to your facility for assembly and further distribution, or could be delivered directly to your customers. Discuss in detail your overall need for assistance with any and all steps in the manufacturing process.

Determine the role of your molded plastic part in the overall production of your finished goods. For instance, if the molded part is just one of many components and requires additional assembly or further steps in the production process, a decision must be made as to who will do the additional work. It could be the molder or it could be you as the customer. Talk to your plastic parts manufacturer about assembly capabilities offered. Secondary operations are now offered by most plastic molders. SPI Industries and SPI Blow molding offer assembly and final processing for several customers. From single part production to total contract manufacturing and fulfillment, whereby we ship directly to your customers from your orders supplied daily.

If the molded plastic part is a standalone product you’ll be able to immediately distribute the parts to your customers. This is generally not the case.

Some manufacturing facilities will handle all of the shipping for you, while other facilities will simply deliver the finished product to you, and you will have to handle the delivery and shipping to your customers.

If you’re ready to make a mock-up design, a plastic prototype, or have a question about the manufacturing process, get in contact with SPI Industries or SPI Blow Molding today. We can help guide you through the entire molded plastic parts manufacturing process.